Innosphere Ventures Client Company Delivers Next-Generation Accuracy in 3D Anatomy Models

Built by new cutting-edge technology, these new 3D prints combine morphological and physiological data for the first time in the same physical model

Tangible Industries, a team of design, engineering and healthcare experts have developed a new, innovative method for 3D printing replicas of patient-specific anatomy that is more accurate than what’s currently available for clinical decision making.

The new method, outlined in the recent issue of 3D Printing and Additive Manufacturing, creates highly detailed, information-rich replicas of a patient’s anatomy by combining a wide range of different data types, including both morphological and physiological data – such as blood flow and velocity, brain matter density and the functionally graded mechanical properties of living tissues, plus much more.

“This new technology allows us to replicate the human body with a greater level of accuracy than what’s ever been available before,” said an author Nicholas Jacobson, co-founder of Tangible Industries, who previously lead a lab focused on computation and design for the Inworks Innovation Initiative on the CU Anschutz Medical Campus.

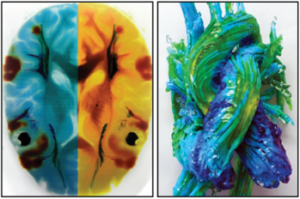

The new approach, developed in Jacobson’s lab, improves on the current single data source approach in 3D printing by combining traditional morphological information, such as data from computerized tomography (CT) and magnetic resonance imaging (MRI) scans, with additional sources of physiological data in the same tangible model. (Figure 1).

To create the advanced 3D printed models, Jacobson partnered with collaborators at Harvard University and LAIKA Studios.

Jacobson and his collaborators say they will offer this method to surgeons for pre-surgical planning, which will allow surgeons to better understand the complete picture of someone’s anatomy.

The paper outlines how the 3D printing method is largely agnostic when it comes to the types of data that can be seamlessly incorporated into the physical models – as this will allow surgeons to draw from a wide range of imaging technologies, such as diffusion-weighted imaging (DWI), diffusion tensor imaging (DTI), functional MRI (fMRI) or even a 3D ultrasound.

This means surgeons can confidently perform complex surgeries, such as brain and heart procedures, more effectively and efficiently by using easy to interpret, custom-tailored and highly complementary medical imaging sources for surgical planning.

Since each surgical procedure often requires its own unique types of data to plan the best course of treatment, this method also allows surgeons to select only those that are specifically relevant, which can greatly de-clutter 3D printed models and significantly streamline the surgical planning process.

“Surgeons are inundated with so much imaging data and they currently aren’t able to view it in a holistic 3D way, so we see this integrated approach as a great benefit for them,” adds Jacobson.

The authors also see the benefits of this type of 3D printing for uses beyond surgery.

“By having morphological information in the same 3D model as physiological data, researchers will be able to understand the complex relationships between different data sources. This approach can help them make a big leap forward in understanding motor neuron diseases and their underlying causes, including for example, in anorexia or Parkinson’s disease patients.”

James Weaver, PhD, one of the study’s co-authors from Harvard’s Wyss Institute, also sees great potential from an educational perspective.

“For example, in the field of cardiology, beyond the value of these models in pre-surgical planning, they can also provide a critical role in better educating medical professionals to identify correlations between cardiac anatomical anomalies and hemodynamics in a patient- or condition-specific context,” said Weaver. “Furthermore, the ability to only depict the relevant types of anatomical or physiological data in a clear, concise and intuitive manner can also be particularly helpful to patients and their families when discussing complex test results and potential treatment options.”

The research presented in this paper was made possible by AB Nexus, a grant program funded by the CU President’s Initiative, CU Anschutz and CU Boulder. The program brings together partnerships across CU campuses among a diverse range of fields to advance science and translational research to improve human health.

Figure 1: By simultaneously combining anatomical and physiological data into high-resolution 3D printed models, it is now possible for physicians to better understand these complex structure-function relationships in a patient-specific context. These two cases, for example, are for visualizing metabolic activity in the brain (left) and the dynamics of blood flow through the heart (right).

About the Tangible Industries

Tangible Industries is an applied biomedical technology company applying our expertise to solve global health issues as a first order of business. We have applied our technology to significantly improve the most important surgical procedure for women who need breast reconstructions, children who need neurosurgery, and infants with cleft palate. By offering a surgical roadmap we can effectively expedite the training and adoption of procedures across primary medical centers in the US, EU, and beyond to a global population. For more information, visit www.tangibleindustries.com